Testing Shooter Designs for FTC 2025-26 Decode

Choosing a Design

We started our FTC season out with a BrainStorming session, throwing out ideas for game strategy and season goals. We established that these are our goals related to the shooter:

Shoot fast

Shoot from any location

Be able to burst fire, rapid fire, and control fire

After establishing these and other general robot goals, we discussed what design options we could consider in order to meet these goals and performed a design review of the different options.

Shooter designs (left to right): 2 Wheel, Single Wheel, Catapult, and Turret

Shooter analysis comparing strengths and weaknesses of different designs (some values derived in the Prototyping and Testing section)

We found that the two wheel shooter was the highest performing in power, distance, and consistency. However, our test data showed that the one wheel shooter was able to shoot with speed and power enough to reach the goal and consistently score artifacts. The added resource cost of the additional motor and wheel for the two wheel design is not worth the excess speed and power that goes beyond what is necessary for strong robot performance.

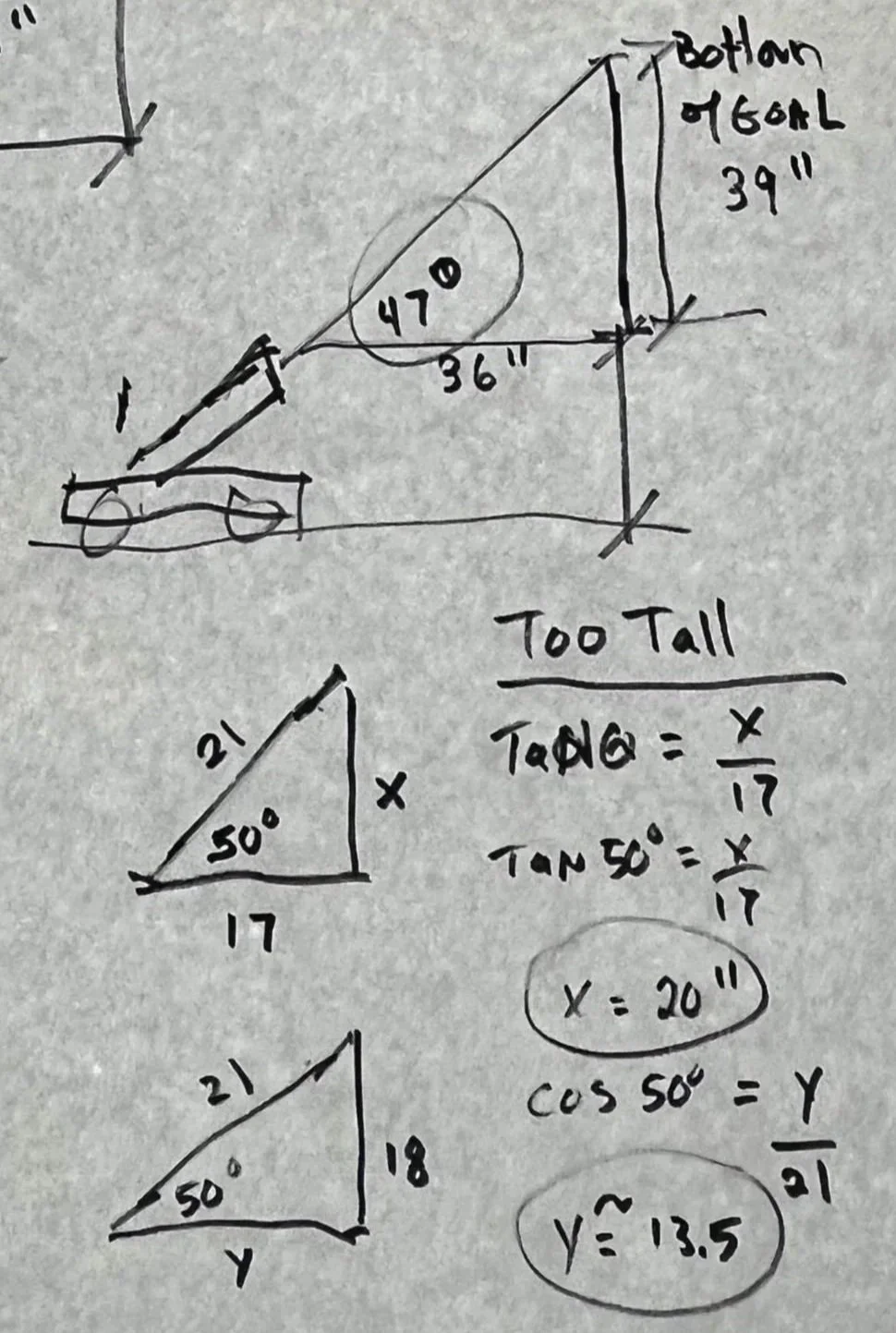

Trig to derive shooter angle

The final decision favored the one wheel shooter design for adequate consistency, power, flexibility, and speed.

Prototyping and Testing

Before beginning prototyping, we had to decide on an angle for the shooter protypes to be positioned at. We determined that within the 17’’ x 17’’ robot base (leaving one inch on each side for lifted parking of alliance bots) the shooter angle would have to be 50º.

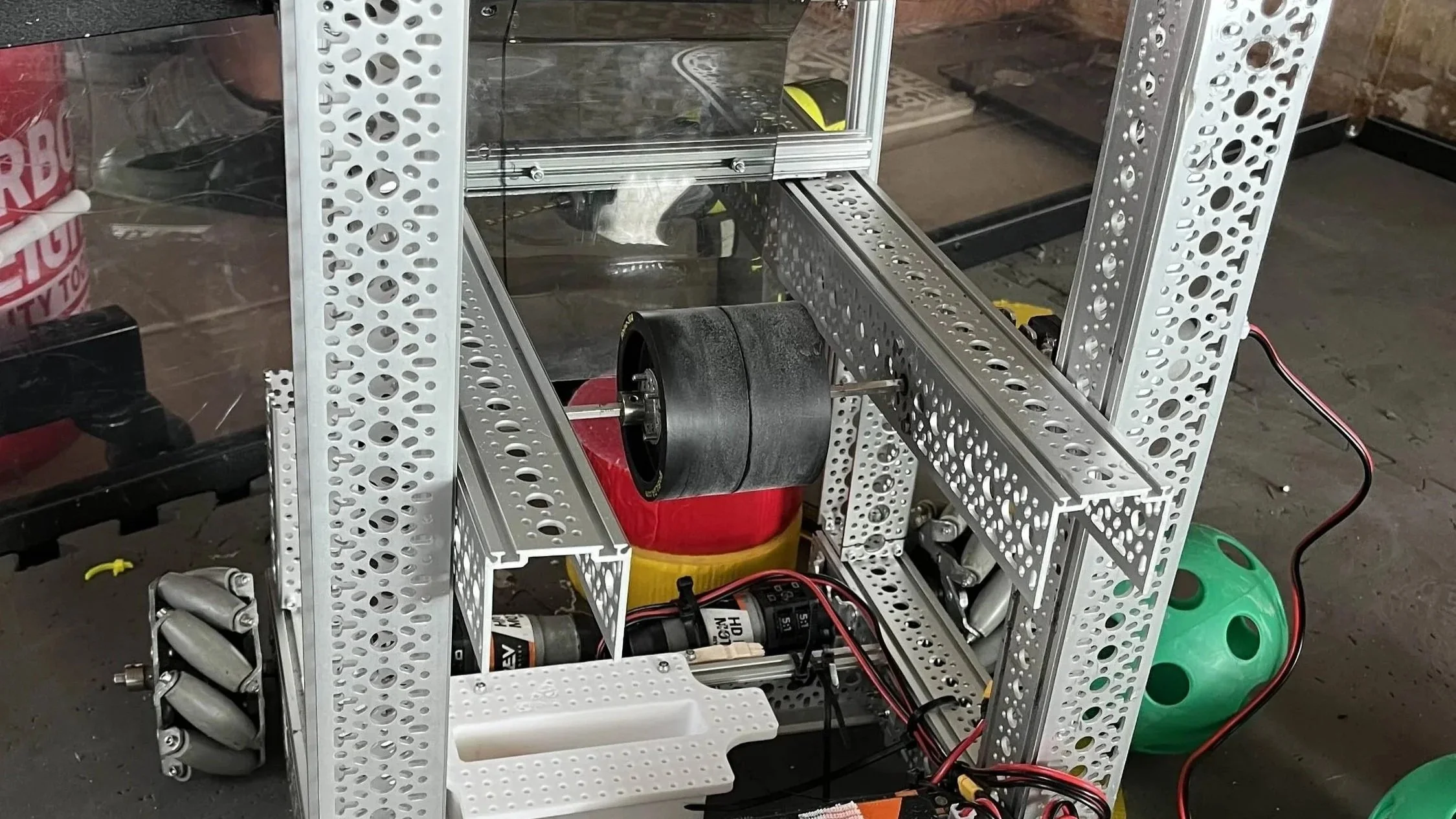

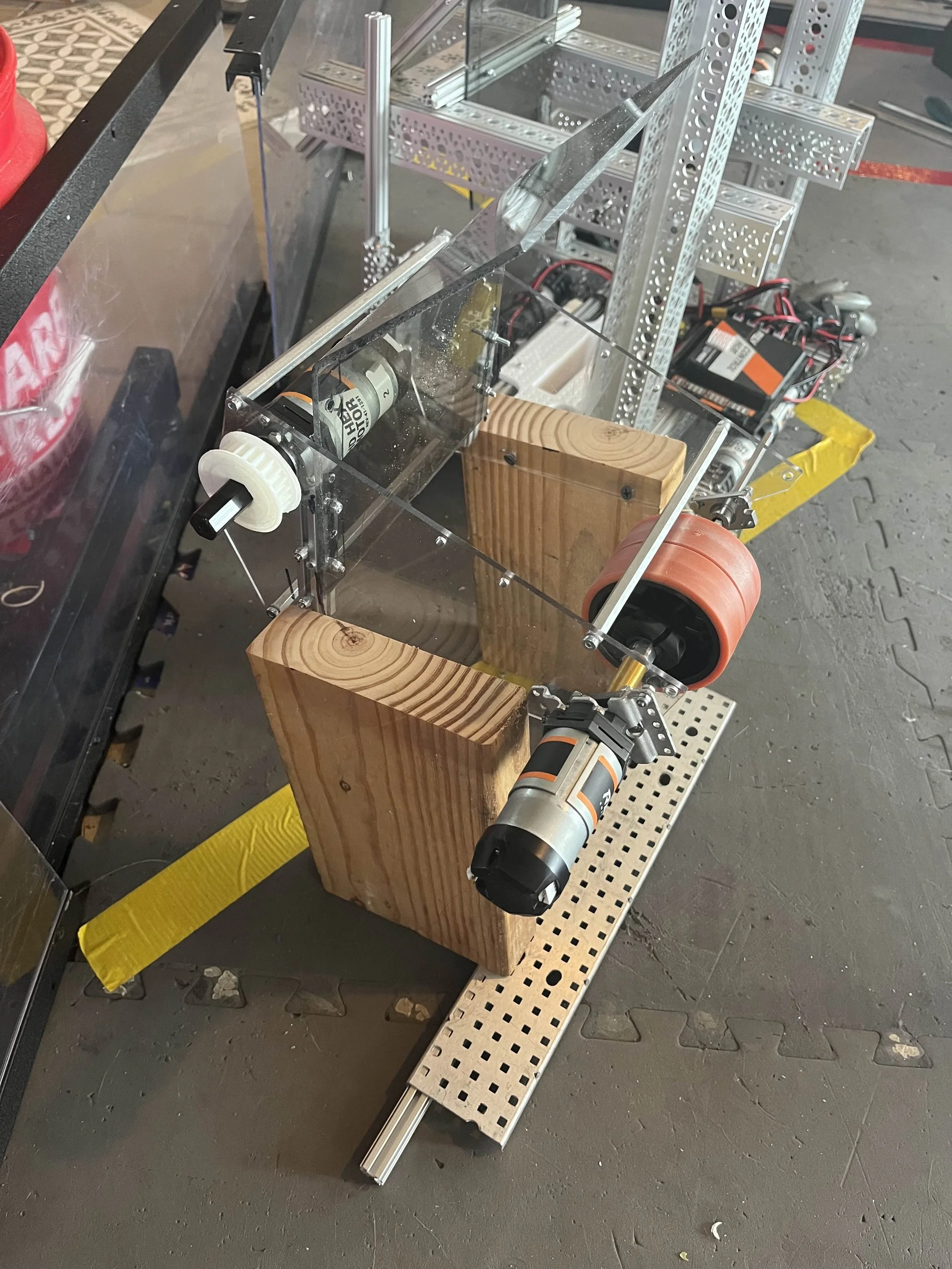

After reaching a shooter angle, we began prototyping different designs to test speed, distance, consistency, and power. We tests one wheel and two wheel designs and tried different sizes of compliance wheels and levels of compression on the artifacts.

Single Wheel Shooter Findings

Findings from testing the single wheel shooter showed that it was effective at scoring goals. However, it was very sensitive to the amount of compression from the metal bracket stop and lacked the flexibility that we preferred.

We decided to attempt a double wheel under shooter to give us more control over consistently applying compression and controlling the artifact’s spin as it is shot. After some success, we varied the types of wheels to optimize distance and consistency.

Double Wheel Shooter with 3” Solid Core Wheels

Double Wheel Shooter with 3” Compliant Wheels

Double Wheel Shooter with 4” Compliance Wheels

Results and Final Design

After various tests and prototypes (as seen above) we found that we favored the double wheel shooter with 3” solid core wheels or 4” compliance wheels.

3” Compliance Wheels: The 3” compliance wheels did not shoot far enough to reach the goal distance or height, despite adjustments to compression and power.

4” Compliance vs 3” Solid Core Wheels: The 4” compliance wheels provided the most flexibility and proved to be more forgiving with any small misalignments or artifact issues. However, they are bulkier than the 3” solid core wheels, which also provided the distance and power needed to score goals from any area of the field. Both were successful in scoring consistent goals with artifacts.